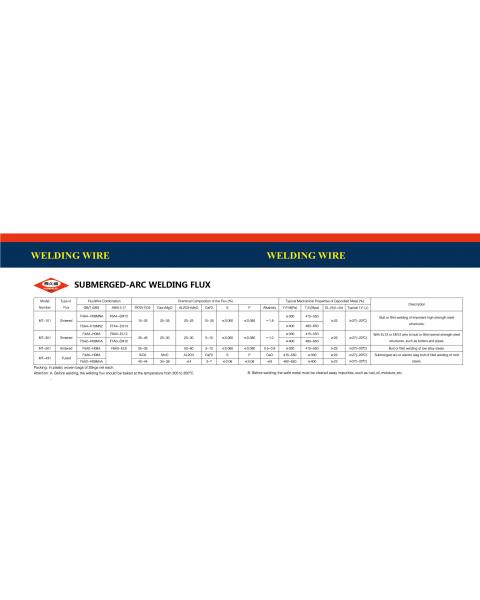

PERMANENT BRAND SUBMERGED-ARC WELDING FLUX

SUBMERGED-ARC WELDING FLUX

Model Number | Tupe of Flux | Flux/Wire Combination | Chemical Composition of the Flux (%) | Typical Mechanical Properties of Deposited Metal (%) | Description | |||||||||||

GB/T 5293 | AWS 5.17 | Sio2+TiO2 | Cao+MgO | AL2O2+MnO | CaF2 | S | P | Alkalinity | Y.P.M(Pa) | T.S.(Mpa) | EL.(%)L=5d | Typical I.V. (J) | ||||

MT-101 | Sintered | F4A4-H08MNA

F5A4-H10MN2

| F6A4-EM12

F7A4-EH14 | 15-25

| 25-35 | 20-25 | 15-25 | ≤0.060 | ≤0.080 | ≈1.8 | ≥330

≥400 | 415-550

480-650 | ≥22

| ≥27(-20℃) | Butt or fillet welding of important high strength steel structures. | |

MT-301 | Sintered |

F5A2-H08MnA | F6A0-EL12

F7A0-EM12 | 35-45 | 20-30 | 20-30 | 5-15 | ≤0.060 | ≤0.080 | ≈1.0 |

≥400 | 415-550

480-650 | ≥22 | ≥27(-20℃) | With EL12 or EM12 wire to butt or fillet normal strength steel structures, such as boilers and pipes. | |

MT-501 | Sintered | F5A0-H08A | F6A0-EL8 | 25-35 | 50-60 | 3-10 | ≤0.060 | ≤0.080 | 0.5-0.8 | ≥330 | 415-550 | ≥22 | ≥27(-20℃) | Butt or fillet welding of low alloy steels. | ||

MT-431 | Fused |

F5A2-H08MnA | SiO2

40-44 | MnO

34-38 | AL2O3

≤4 | CaF2 3-7 | S

≤0.06 | P

≤0.08 | CaO

| 415-550

480-650 | ≥330

≥400 | ≥22

≥22 | ≥27(-20℃) ≥27(-20℃) | Submerged arc or electro slag butt of fillet welding of mild steels. | ||

Packing: In plastic woven bags of 25kgs net each.

ATTENTION: A. Before welding, the welding flux should be baked at the temperature from 300 to 350°C

B. Before welding, the weld metal must be cleared away impurities, such as rust, oil, moisture, etc.